The world of diecast cars is a passionate hobby, and with the advent of 3D Bot Makers, enthusiasts have a whole new avenue to explore their creativity. This guide unveils the top 5 essential tips to help you master 3D Bot Maker for diecast car customization. From choosing the right software to the final assembly, we’ll cover the crucial steps, empowering you to design, create, and showcase stunning diecast models. Get ready to transform your passion into tangible, personalized works of art. Embrace the future of diecast modeling and unlock a new level of customization capabilities.

Mastering 3D Bot Maker for Diecast Cars

Mastering 3D Bot Maker for diecast cars requires a blend of technical skill and artistic vision. It is not simply about knowing the software; it is about understanding the principles of design, the limitations of the materials, and the techniques of 3D printing. Start by familiarizing yourself with the basics of 3D modeling. Learn to manipulate shapes, create intricate details, and understand how these elements translate into a physical object. Experiment with different design concepts. Use online tutorials to deepen your knowledge and skills, and learn how to troubleshoot common problems and refine your designs.

Choosing the Right 3D Bot Maker Software

The foundation of any successful 3D diecast project lies in choosing the right software. Several options cater to different skill levels and needs. Consider the software’s user interface, features, and compatibility with various 3D printers. Some software, like Tinkercad, is ideal for beginners due to its intuitive design. Other options, like Fusion 360 or Blender, offer more advanced features and greater control over the design process. Evaluate the learning curve, community support, and cost before making a decision. Experimenting with free trials can help you find the best fit for your workflow and project complexity.

Exploring Software Options

When exploring software options, look beyond the basic features. Assess the available modeling tools, rendering capabilities, and export options. Consider software that offers specific functionalities relevant to diecast car design, such as precise measurements, surface detailing, and the ability to easily incorporate features like windows, wheels, and other components. Check for compatibility with your chosen 3D printer and ensure that the software supports the file formats required for printing. Some software is free and open source, while others come with a subscription fee or require a one-time purchase. Weigh your budget against your needs and the features offered by each software option.

User Interface and Features

The user interface of your 3D modeling software significantly impacts your workflow. A well-designed interface is intuitive, allowing you to navigate the software easily and access the tools you need. Look for features like customizable toolbars, keyboard shortcuts, and a clear visual representation of your model. The software should provide comprehensive features for designing diecast cars, including precise measurements, surface detailing, and the ability to integrate various components. Evaluate the availability of tutorials, community forums, and customer support, as these resources are invaluable when learning and troubleshooting.

Essential Tools and Techniques for Diecast Design

Designing diecast cars with 3D Bot Maker requires a grasp of essential tools and techniques. Mastering these elements is crucial for creating realistic and detailed models. Start with the basics of 3D modeling, learning how to create and manipulate shapes, use boolean operations to cut and combine shapes, and apply textures and materials. Experiment with features like extruding, beveling, and smoothing to refine your designs. Understanding how to create accurate joints, use precise measurements, and plan for the printing process will also improve the design quality and build success. Practice these techniques to develop a systematic and efficient workflow.

Precision Measurements and Scaling

Precision is paramount when designing diecast cars. Accurately measuring and scaling your designs is essential for a realistic final product. Use precise measurements based on the dimensions of the original car or the diecast model you are replicating. Learn to use the software’s measurement tools and ensure that your designs accurately reflect the proportions and details of the real car. Consider the limitations of the 3D printing process. Pay attention to minimum wall thicknesses and small features that might not print correctly. Proper scaling will ensure that your printed model matches your design in size and detail.

Surface Detailing and Texturing

Surface detailing brings your diecast cars to life. Add realism by applying textures, such as paint finishes, carbon fiber, or chrome accents. Use the software’s tools to create intricate details like grilles, headlights, and emblems. Experiment with bump maps and normal maps to simulate surface imperfections, enhancing the visual appeal of your models. Consider the printing process. Test your surface details before printing to ensure they are clear and well-defined. Proper surface detailing separates a good design from a truly exceptional diecast model.

Prototyping and Testing Your Designs

Prototyping and testing are crucial steps in the 3D Bot Maker process. Before committing to a full-scale print, create a small prototype to check for design flaws and printability issues. This process helps you identify any adjustments needed before printing the final model. When testing, examine the fit of components, the clarity of details, and the structural integrity of the design. Consider the material properties. Test the design with the specific 3D printing material you intend to use. Prototyping saves time and resources and ensures that your final diecast car meets your expectations.

3D Printing Technologies for Diecast

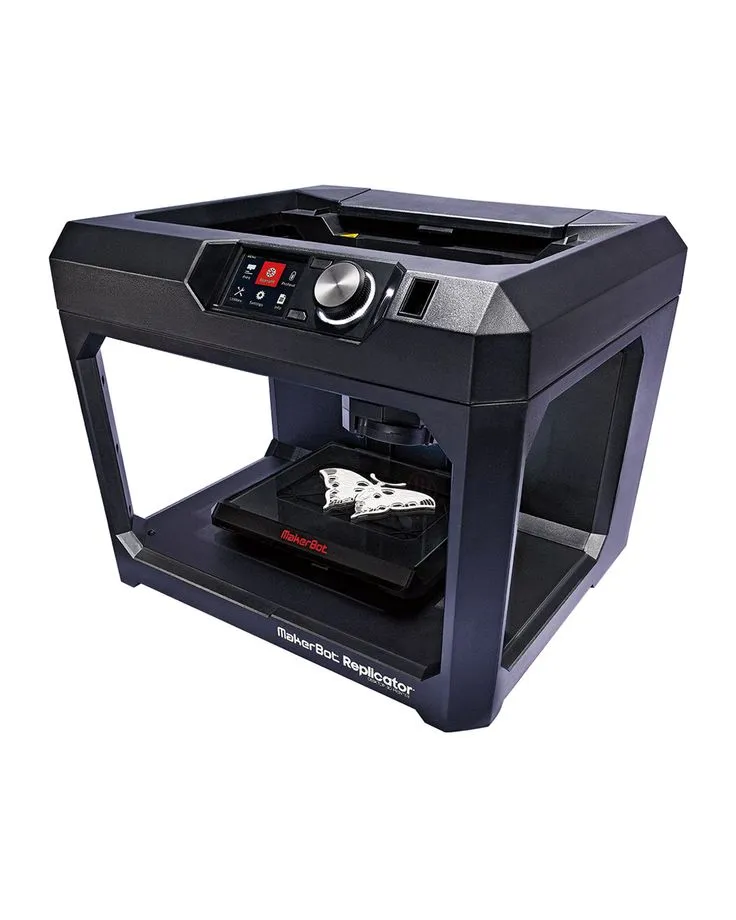

Choosing the right 3D printing technology is essential. Fused Deposition Modeling (FDM) is common, using heated plastic filaments. Stereolithography (SLA) and Digital Light Processing (DLP) use resin and offer higher detail. Consider the cost, build volume, and material options of each technology. FDM is often more affordable, while SLA and DLP provide finer details, making them suitable for intricate diecast car designs. Research the capabilities of each technology and select one that aligns with your needs and budget. Be aware of the post-processing steps required by each technology, as this will influence your decision.

Selecting the Right Printer

When selecting a 3D printer, research the printer’s specifications, build volume, resolution, and material compatibility. Consider the types of materials you want to use for your diecast cars. FDM printers typically use a variety of plastics, while SLA/DLP printers use resins. Evaluate the printer’s reliability, ease of use, and maintenance requirements. Explore the printer’s community, as a strong community often provides useful resources, tutorials, and support. Read reviews and compare different models, focusing on the features that are most important to you.

Material Considerations

The material you choose impacts the look, feel, and durability of your diecast model. Common materials include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and various resins. PLA is user-friendly and biodegradable, while ABS is durable and can withstand higher temperatures. Resins offer fine details but often require more post-processing. Consider the material properties, such as strength, flexibility, and heat resistance. Research the available material options for your selected 3D printing technology. Choosing the right material will directly influence the quality and longevity of your diecast car design.

Post-Processing Techniques for Diecast Cars

Post-processing is critical to achieving a professional finish for your diecast cars. This involves several steps to refine the printed model, including removing support structures, sanding, priming, painting, and applying clear coats. The post-processing steps vary depending on the printing technology and materials used. Proper post-processing enhances the appearance and durability of your models. Invest time in learning these techniques to transform a 3D-printed model into a high-quality diecast car.

Cleaning and Finishing

After printing, clean the model to remove support structures and any excess material. Carefully detach supports and trim any rough edges. Sanding is essential for achieving a smooth surface. Start with coarser grits and gradually move to finer grits to remove imperfections. Apply a primer coat to prepare the surface for painting. Choose a primer compatible with the materials used. Allow the primer to dry completely before proceeding. Proper cleaning and finishing will create a smooth, flawless surface for your diecast car design.

Assembly and Detailing

Assembly and detailing transform individual components into a complete diecast car. Carefully assemble the different parts, ensuring a snug fit. Use appropriate adhesives and fasteners, but consider the long-term look and feel of your car. Apply paint and decals to create a realistic appearance. Add small details like lights, windows, and interior elements. Consider adding weathering or other effects. Assembly and detailing are where the design comes to life and is an opportunity to showcase creativity.

Sharing and Showcasing Your Creations

Sharing and showcasing your diecast car creations is a rewarding part of the process. Join online communities and social media platforms. Share your designs, progress, and final models with others. This will provide inspiration and feedback. Consider participating in online contests or exhibitions to gain exposure. Start a blog or portfolio to document your work and share your experiences. The diecast community is welcoming. Sharing your work with other enthusiasts can inspire you. Remember to give credit. Sharing your creations provides you with a platform to get inspired and stay connected with the diecast modeling community.

With these 5 tips, you’re well-equipped to start creating amazing diecast cars using 3D Bot Maker. Remember that practice and experimentation are key. Enjoy the journey of design and creation and share your passion with the diecast community. Happy designing!